Rubber-metal Adhesion promoter

Our vulcanization adhesion promoters allow you to bond rubber to other materials.

What are vulcanization adhesion promoters?

These adhesion promoters are used in the rubber processing industry, among others, to create adhesion and chemical bonding between rubber or elastomers and other materials such as metals or textiles. These adhesion promoters are therefore called vulcanization adhesion promoters, as the adhesion between the rubber and the substrate only forms during the vulcanization process.

Vulcanization adhesion promoters often contain compounds or chemicals that promote and accelerate the vulcanization reaction. This cross-links the molecules of the rubber or elastomer, giving the material greater strength, durability and elasticity.

The vulcanization adhesion promoter ensures efficient and reliable cross-linking between the polymer chains and other materials.

The specific composition varies depending on the requirements of the specific rubber product and may contain sulphur compounds, peroxides or other chemical substances that promote vulcanization in rubber compounds.

Our adhesion promoters for rubber-metal

SI COATINGS 609177-30 (One-coat adhesion agent for rubber adhesion composites)

SI COATINGS 609177-30 is a one-component adhesion promoter for bonding NBR, CR and ACM to metals. The adhesive bond is created during vulcanization by chemical absorption. Articles manufactured with SI COATINGS 609177-30 have very good resistance to solvents and technical oils as well as good temperature resistance.

SI COATINGS 619181-30 (one-coat system for nitrile and chloroprene rubber compounds)

SI COATINGS 619181-30 is a special one-coat adhesion promoter developed for bonding nitrile, chloroprene, ACM and ECO rubber compounds to metals. Adhesion is achieved by chemical absorption during vulcanization.

The product is preferably used in the manufacture of sealing parts.

SI COATINGS 619185-10 (Universal adhesion agent for rubber/rubber adhesion composites)

SI COATINGS 619185-10 is a versatile bonding agent that bonds various vulcanized and unvulcanized elastomers to each other as well as to metals and plastics. SI COATINGS 619185-10 binds rubber compounds based on NR, IR, SBR, NBR, CR, IIR, CI IIR, CSM and EPDM. For metal joints, a two-coat system with the primer SI COATINGS 807099 in combination with SI COATINGS 619185-10 is recommended. The product is particularly suitable for lining containers with rubber and for recoating rollers.

SI COATINGS 619190-10 (universal adhesion agent for rubber/metal adhesion composites with insensitive surface)

SI COATINGS 619190-10 is a universal bonding agent specially developed for heat-resistant joints. SI COATINGS 619190-10 binds rubber compounds based on IR, IIR, NR, NBR, BR, SBR, CR, Vamac and many plastics. A primer of type 801093-15 or 807099 is required on metallic substrates or workpieces. SI COATINGS 619190-10 is particularly robust due to its surface hardness, even before vulcanization.

SI COATINGS 629184-10 (Universal adhesion agent for rubber/metal adhesion composites)

SI COATINGS 629184-10 bonds NR-, IR-, BR-, SBR-, CR-, NBR-, IIR- and CSM-based rubber compounds with metals and many plastics. The parts bonded with this adhesion promoter have very good resistance to oil and solvents. The use of SI COATINGS 807099 primer increases corrosion resistance and temperature resistance in particular. The SI COATINGS 807099 and SI COATINGS 629184-10 adhesion promoter system is particularly suitable for soft NR and NBR compounds in both the TM and IM processes.

SI COATINGS 629186-10 (Universal adhesion agent for rubber/metal adhesion composites)

SI COATINGS 629186-10 binds especially EPDM and various rubber compounds for which SI COATINGS 629184-10 is still too “polar”. The property profile of the vulcanized workpieces corresponds to that of SI COATINGS 629184-10. The use of a primer such as SI COATINGS 807099 is absolutely necessary on metal substrates.

SI COATINGS 807099 (Universal primer for rubber adhesion composites)

SI COATINGS 807099 is a universal adhesion promoter. The primer can be used, for example, with the universal adhesion promoter SI COATINGS 629184-10, 629186-10 or SI COATINGS 619190-10. SI COATINGS 807099 gives the rubber/metal bond excellent corrosion resistance and generally good resistance to hydrolytic influences. These parts also have excellent dynamic and thermal stability. Even on substrates that are difficult to bond, perfect adhesion can often be achieved with SI COATINGS 807099. In addition, SI COATINGS 807099 is an excellent one-coat binder for nitrile rubber (NBR), which is particularly suitable for the manufacture of sealing parts. Articles produced with SI COATINGS 807099 have very good resistance to technical oils.

SI COATINGS 629080-10 ("two in one" universal adhesion agent for rubber adhesion composites)

SI COATINGS 629080-10 is a universal adhesion promoter with particularly good metal adhesion. A metal primer can usually be dispensed with “two in one”. If required, SI COATINGS 629080-10 can also be used as a two-coat system. In this case, the product is used as a primer. With two-layer systems, care must be taken to ensure that the first layer is not stressed beyond the usual vulcanization temperature. SI COATINGS 629080-10 combines rubber compounds based on NR, IR, BR, SBR, CR, NBR, IIR and CSM with metals and many plastics. The parts bonded with this bonding agent have very good resistance to oil and solvents. The SI COATINGS 629080-10 adhesion promoter system is particularly suitable for soft NR and NBR compounds in the TM and IM process. SI COATINGS 629080-10 is also suitable as an adhesion promoter for vulcanization in salt baths.

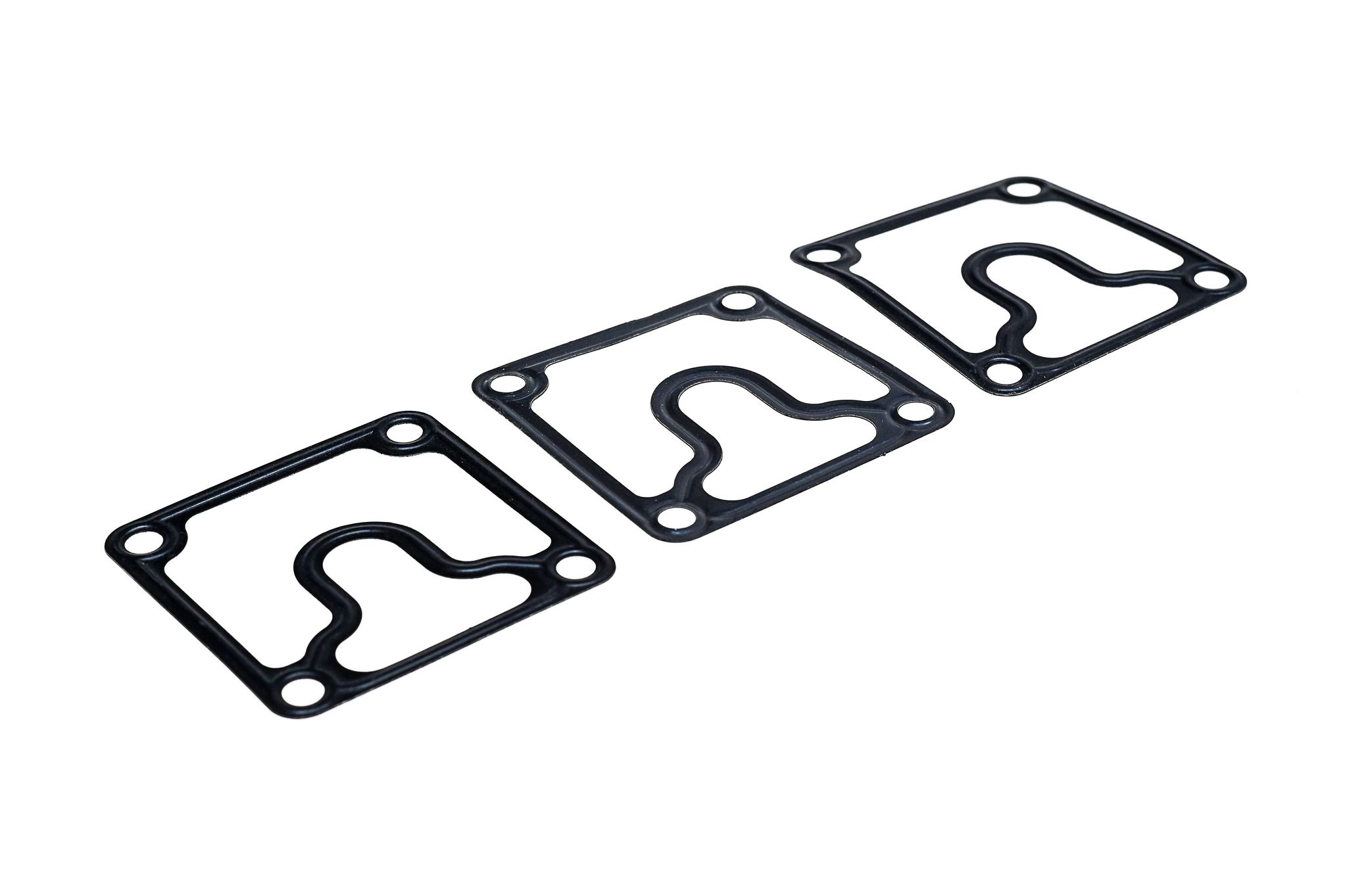

Coated seals

Coated seals

Damping elements

NR with internal PA frame

Test specimens for laboratory tests